15 December 2021

Would you like to find out how to create a piece of jewellery? G-Silver helps you to understand and guides you through the steps of creation. Thanks to our expertise and our skills in this field, we carry out all the following steps that will be outlined for the creation of custom-made jewellery. This could be a ring, a charm…

We can therefore offer you a base, to which several techniques can be added. G-Silver, supplier of 925 sterling silver jewellery, can accompany you throughout your project.

Firstly, it is necessary to carry out research beforehand in order to choose which materials to use metal, beads, stones… This is the stage that will combine inspiration, reflection, imagination and research by consulting magazines, websites……

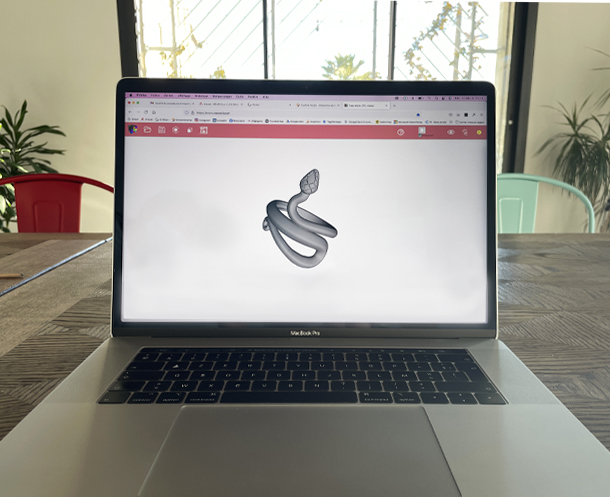

The creation of your design can be done on paper. It is important that the sketch includes all the details concerning materials, colours, dimensions, curves, and finishing’s. However, it is also possible to create a 3D model to be more precise in reproducing curves, shapes, leaks and spacing… G-Silver can help you do this. Our workshops have all the necessary equipment.

Once the choice of your jewellery has been determined and the design created, the most suitable manufacturing techniques must be used.

It is also possible to create a 3D model to be more precise

It is also possible to create a 3D model to be more precise

After your design or 3D modelling, the next step is to make the wax. This can be done by hand, for example by sculpting a ring or pendant directly on a wax tube, or with a 3D printer. The creation of the model is the most important step.

If you want to make a series of findings after creating your first model, you must make a casting. This allows you to replicate your jewellery identically. The casting can be made of rubber, plaster etc…

Once we have drawn the waxes for your jewellery from your mould, casting can be carried out: it allows us to cast several jewellery pieces of the chosen model in one go. The plaster must be poured into a cylinder, which surrounds your waxes assembled on a casting wax tree. The cylinder is placed in the furnace and the metal is injected into it, replacing the wax, a technique known as “lost wax”. The melting temperature must be very high and depends on the metal. Then comes the cooling stage to remove the plaster from the stem. Finally, the pieces are sawn off one by one so that they all come off the stem.

The plaster must be poured into a cylinder, which surrounds your waxes assembled on a casting wax tree

The plaster must be poured into a cylinder, which surrounds your waxes assembled on a casting wax tree

First, the setting will allow you to put the chosen stones on your charm or ring. This can be precious stones or other stones that are very trendy. It is a step that requires precision and patience. Then comes the polishing which will make the jewellery shiny.

You can also add an engraving to your jewellery to personalise it so that your unique piece holds a message.

It is also possible to carry out rhodium plating, which prevents the metal from oxidising by soaking the jewellery in a rhodium bath for a few minutes. This brings out a beautiful white or black shine. G-Silver uses this technique, which makes it possible to offer jewellery such as rings and pendants in black or white rhodium plating.

We carry out different techniques on sterling silver findings with various possible galvanisations:

- Silver

- Pink gold

- Yellow gold

- White rhodium

- Black rhodium

Quality control must of course be carried out at each completed stage.

Prevents the metal from oxidising by soaking the jewellery in a rhodium bath for a few minutes

Prevents the metal from oxidising by soaking the jewellery in a rhodium bath for a few minutes

Skip to content

Skip to content